Why

FEELO®

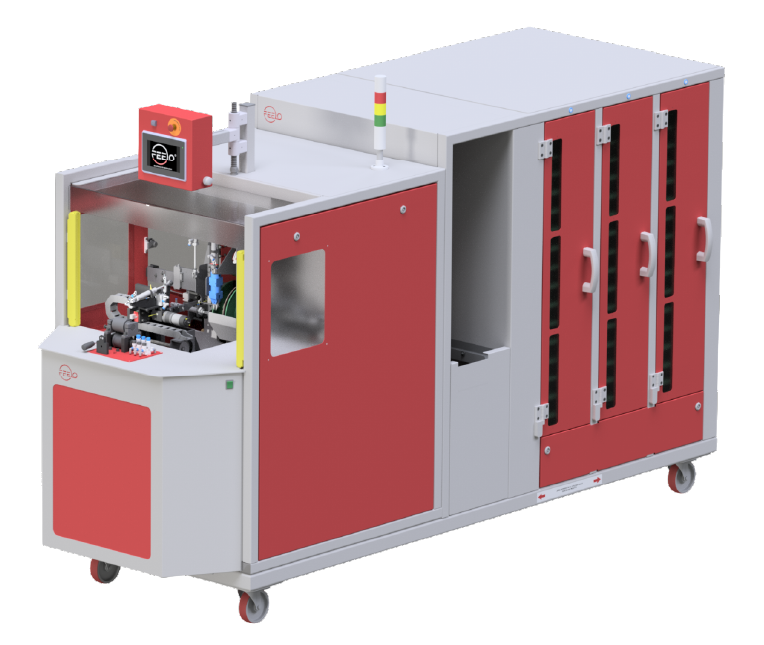

Fully automatic winder

Neat winding

Compact footprint

In line with extruder or unwinder

Low operational cost

Winding Speed

Up to 300 m/min

Filament Diameter

1.75 or 2.85 mm

Spool Diameter

200 mm

QC System

100%

Our automatic winder comes in two versions, each with a different locking system:

FEELO® PRIMA Winder

compatible with FEELO® SPOOL 2.0

We have upgraded our spool locking system to 2.0, offering fully compatibility across all 3D printer AMS models. Our locking system securely holds the filament during transport without the need for additional material like labels, tapes, or ties, making it as eco-friendly as possible.

This innovative feature also simplifies the spool change process, allowing the filament to be easily secured, even mid-spool, with a quick and simple action.

Fully automatic winder

No consumable required

Neat winding

Compact footprint

In line with extruder or unwinder

Low operational cost

FEELO® DOTs Winder

compatible with STANDARD SPOOL

We have developed the FEELO® DOTs Winder, an innovative solution deisgned specifically for standard spools. What makes it unique is its distinct locking system; a small DOT is applied at the end of winding, firmly securing the filament.

Fully automatic winder

Compatible with standard spools

Neat winding

Compact footprint

In line with extruder or unwinder

Low operational cost

Main

Features

The fully automatic doffing system represents a breakthrough in manufacturing efficiency.

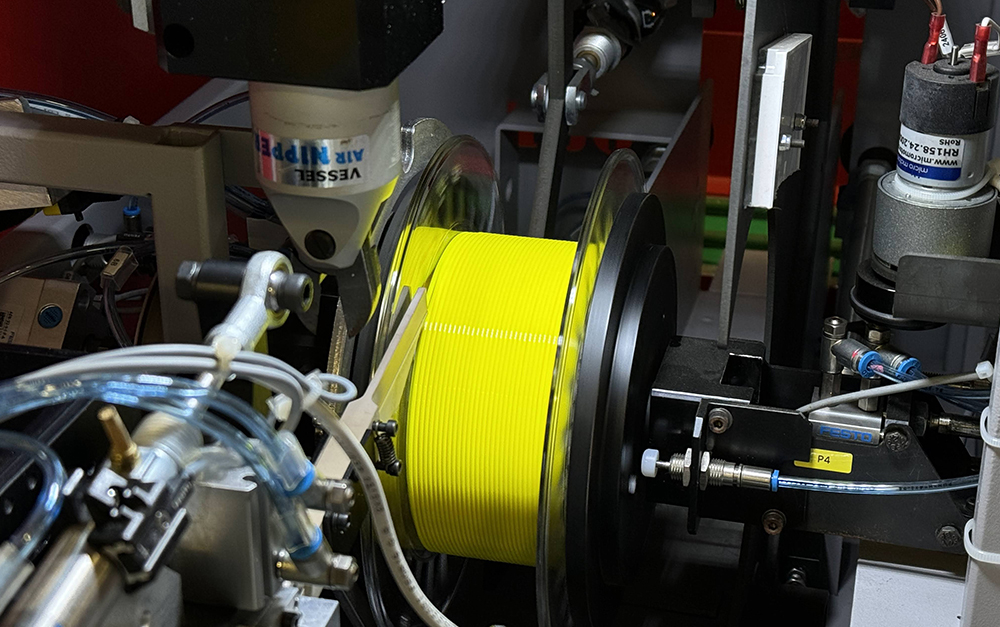

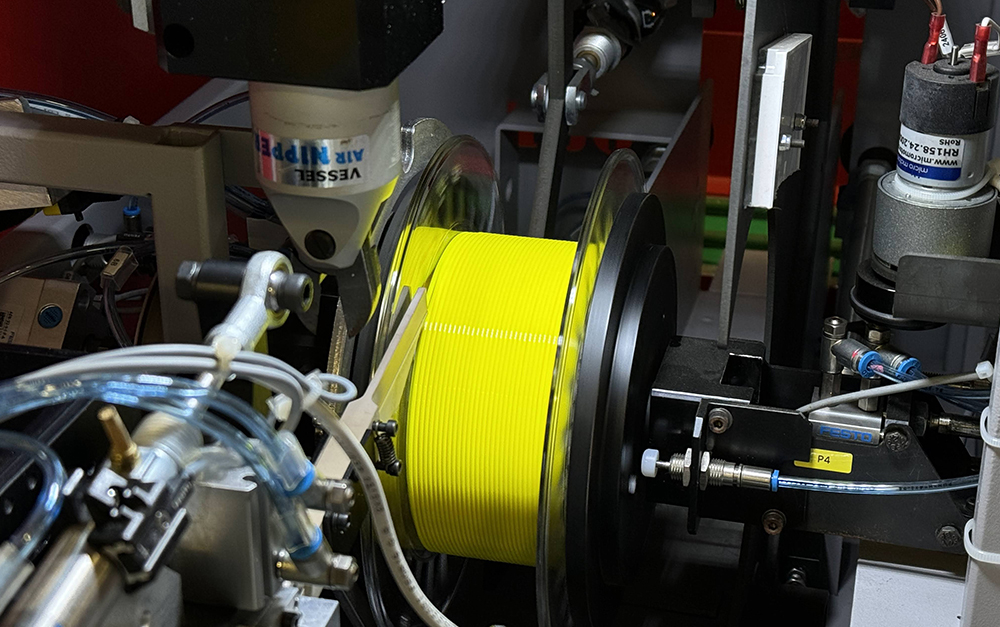

Its ability to achieve perfect parallel winding is key to ensuring high-quality production.

Additionally, the empty/full spools buffer provides intelligent resource management, ensuring uninterrupted production.

Being directly installed after the extruder or unwinder makes this system highly convenient in terms of layout and space management. Its compact footprint allows for optimal space utilization, enhancing overall plant efficiency.

FEELO® ZEERO

Why

ZEERO

Large format-spools

Neat winding

Compatible with all filament

Plug & Play with all extrusion lines

Compact footprint

User-friendly HMI

Winding Speed

Up to 300 m/min

Filament Diameter

1.75 or 2.85 mm

Spool Type

Refil carton tube

200 mm diameter

300 mm diameter

350 mm diameter

Quality Control

Plug & Play

FEELO® Production line

Packaging Line

It is possible to complete the line with equipment such as custom reel labeling, custom reel engraving, film wrapping, or robotic arms that automatically and precisely arrange reels onto pallets ready to be shipped to the customer.

Buffer

Up to 100 spools (750 gr / 1 kg) ready to feed the FEELO® PRIMA Winder.

This leads to higher output per production hours, higher line speed and lowered operational cost.

FEELO® + Buffer Spool Quality Control

Automatic spool quality control process with detection/removal of faulty ones.

Parameter Screen

User frendly interface for simple opeartor calibrations as well as low-level and complex technical configuration.